| Who we are? | What we offer? | Our experience | Why choose us |

| Who we are? |

| We are a professional mold supplier. |

| WIN-PLASTICS is a full-service plastic & plastic mold factory located in Dongguan City China where is nearby to Hong Kong China.

WIN PLASTICS History:

|

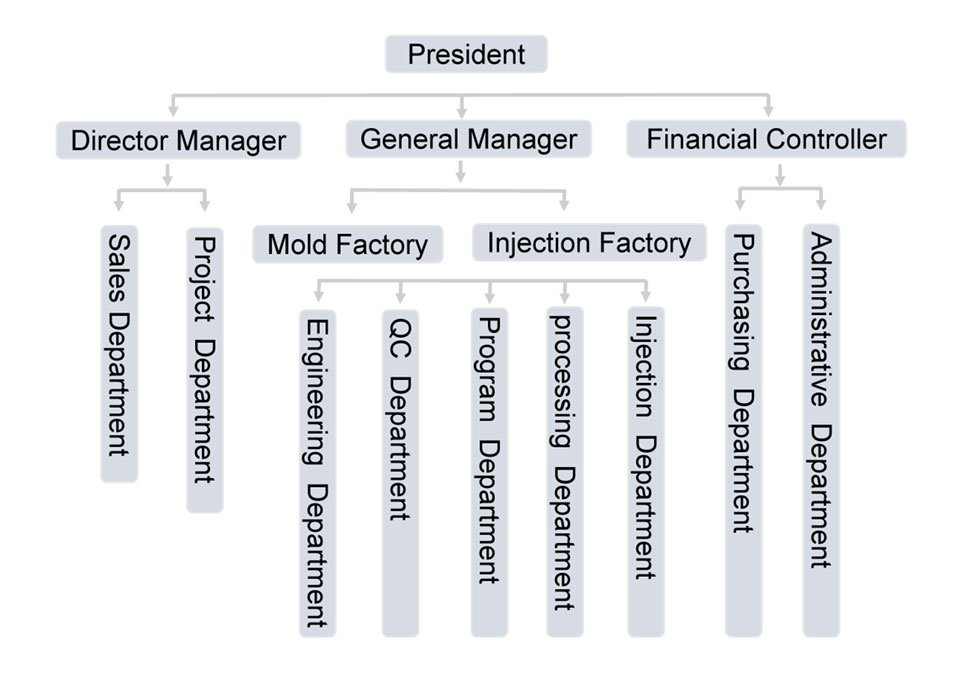

WIN PLASTICS Organization Chart: |

|

WIN-PLASTICS Capabilities: |

| Design: |

| Engineering is the guidance of the production and tool making which will make the engineering progressive and perfect. |

| Engineering is designing mould layout and also provides more available solution for customer's reference. |

| Our engineers use Unigraphics for mold design and CNC programming, we support various kinds of formats such as dxf, dwg, igs, step, x-t, sldprt, etc. We also use other software as below: |

|

| |

|

| |

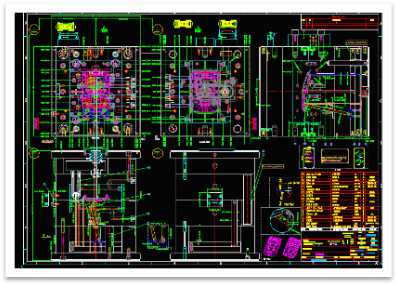

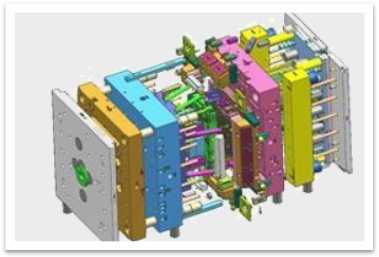

| 2D design | 3D design | Moldflow |

| Processing: | |||||||

|

Win-PLASTICS owns the world advanced equipments like CNC, EDM, WCM, CMM . . . We use advanced equipments to improve production speed, processing precision, thus to show high quality mold to our customers.

| |||||||

|

| ||||||

|

| ||||||

| Manage: |

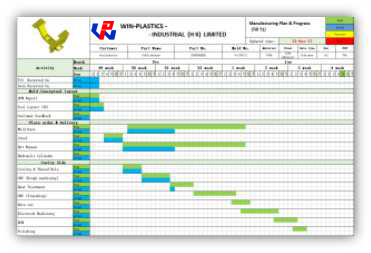

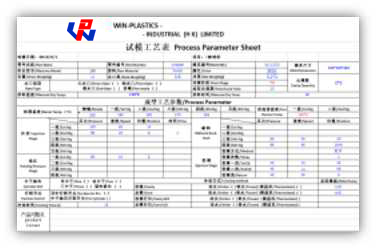

| We has built a full project management system to control quality and guarantee delivery from designing, manufacturing, mold tryout, molding and shipping. Our engineer and sales work together to keep good communication with customers. The weekly report with clear pictures will be updated every Monday. |

|

|

|

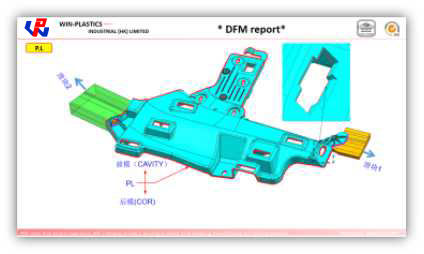

| DFM report | Weekly report | Parameter report |

| There are three meetings for each project: One for how to design, one for how to manufacture and one for how to do perfect next time. Each meeting will let our engineers and tool makers learn more experience each other and promote our quality day by day. |

| With more than 15-year-experience,Win is keeping moving in focusing on plastic mold designing manufacturing and injecting products. Webmaster |